April, 12 2023

Dermalogica’s logistics director discusses how to think about a 3PL transition

“Any business has its risks. But getting your products into customers’ hands faster has never made less money.”

It’s clear, in 2023, that rising costs and supply-chain issues are part of a new reality. Shipping has not avoided the fallout, and the uncertainties of the last few years have had an outsized effect on carriers. Inflation, rate increases, fuel surcharges, delays, and other bumps have changed what we fundamentally understand about shipping.

Because shipping is the backbone of ecommerce, every retail executive must look at shipping and fulfillment to determine whether the established solution is still the right one.

Third-party logistics solutions can mitigate these issues. But a business leader examining the costs and unknowns around a third-party logistics (3PL) solution may be hesitant to take the leap.

A 3PL may not be the right solution—or at least not the right solution today. But to best make the decision, leaders need to understand the pros and cons, do the math, and have a little faith.

So, when is it worthwhile? Dermalogica director of US logistics Jason Brown shares insights in a conversation with FenixCommerce.

Third-party logistics covers outsourcing any procurement or distribution services to an external vendor. For ecommerce, this covers inventory, warehousing, shipping, and other functions related to fulfillment. By outsourcing these activities, an ecommerce company can gain efficiencies, broaden their geographic reach, and reduce certain types of overhead in exchange for some up-front transition processes and vendor fees.

These are factors to consider before making a switch.

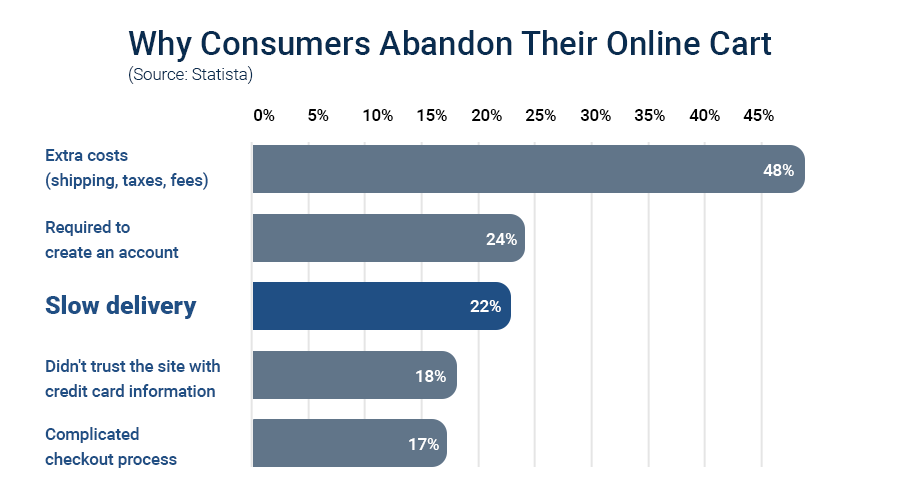

Customers’ intolerance of longer shipping times (5+ days) is growing. (In 2023, according to Forbes, 22% of customers drop out of an online shopping session because shipping is too slow.) Popularized by Amazon, short delivery windows—even within a few hours—mean that customers sometimes find it faster to arrange delivery than shop in person. These speeds are enabled by the multilocation structure of a 3PL.

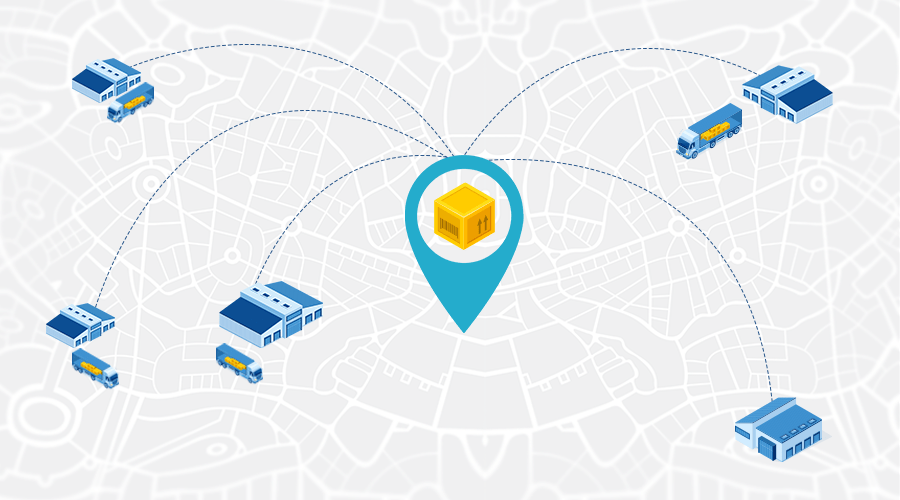

Brown says, “If you think you need to get faster shipping in order to get closer to your customer, that might be one reason to consider multiple locations.” Using a 3PL’s multilocation network, geography becomes an asset, not an obstacle, to fulfillment.

However, retail executives may be wary of taking on the costs of multiple locations: staff, property, and maintenance expenses, to say the least. Additionally, the more complex your distribution-center structure becomes, “the better you have to be about balancing your inventory, forecasting what you’re going to ship, so you have the right stuff in the right place at the right time,” Brown says.

Here’s where 3PL efficiency can help: brands benefit from an existing multilocation structure and expertise while only paying a fraction of the vendor’s overhead. Service-level agreements (SLAs) with the 3PL will govern how to best leverage this efficiency. A key part of any 3PL SLA is forecasting—providing the vendor with solid estimates (typically ±20%) on expected sales volumes (promotions, product launches, etc.) to manage staffing costs.

Integration costs can create hesitation in initiating a 3PL relationship, but thoughtful integration is critical to a successful ongoing solution—if for no other reason than the outsized benefit it has on inventory management. Accurate inventory numbers are one part of delivering as promised. And for ecommerce brands tied to the same warehouse as larger wholesale, corporate, or distribution entities, the risk of inventory being repurposed without their knowledge is real. (Brown refers to this as the “robbing Peter to pay Paul” scenario.)

So, inventory needs to be tightly synced, integrated, and reported—a challenge without strong operating systems. The tools to manage inventory (warehouse and order management systems; forecasting) can be costly to implement independently but come within reach with a 3PL relationship.

As Brown notes, “A 3PL will have a solid WMS that (must be) tightly synced to your ERP.” Additionally, an effective OMS is necessary, but it can be expensive for a growing company. Many 3PLs have their own custom-built solutions they can license to clients—reducing the cost of implementing a high-quality tool. Also available on the market are inexpensive, AI-based order-routing optimization tools that operate as an OMS and integrate easily with 3PLs.

Having access to reliable data—SKU levels, past sales history, fulfillment performance—not only saves time remediating but can be used for forecasting. Access to an integrated, reliable, and robust WMS, OMS, or both, which a 3PL can provide, makes a difference.

At the end of the day, the promise of delivery to a customer falls on the brand, whether using a 3PL or staying in-house. A missed delivery promise not only costs time in resolution but can lose the relationship. So, in addition to inventory management, brands must monitor carrier performance.

Brown says, “It’s up to you to then manage the relationship after (the order is shipped). You need to know the order shipped, it shipped complete, and where it shipped from and have confidence it will arrive in good condition, so you can go back to your customer and make the delivery promise.”

If your inventory synchronization ensures that the right item ships from the right 3PL location, carrier performance monitoring makes sure the item is delivered to the customer on time. And 3PLs can assist with both insights.

Stakeholders may be concerned by possible lower margins, but the increased reliability and potential volume of 3PL fulfillment can lead to greater revenue.

Engaging with a 3PL is “rarely cheaper” than doing it yourself, Brown notes, “but the capability is better. They may be willing to work six, seven days a week, two shifts, 24 hours a day. From there, it becomes a math equation. Our margins may compress, but our revenue will grow by X factor.”

So, is it the right time to engage a 3PL? Like many business decisions, it depends on the math and a little imagination. “‘We know this is risky,’” Brown imagines the conversation. “Any business has its risks. But getting your products into customers’ hands faster has never made less money. There’s a lot of blue sky, and you have to have a little bit of faith.”

FenixCommerce is a leading provider of customer delivery experience management, helping retailers deliver better, every step of the way. Founded in San Jose in 2017, FenixCommerce is trusted by the fastest-growing ecommerce brands and retailers including Men’s Wearhouse, Dermalogica, Jos A. Bank, Grunt Style, Lord & Taylor, and Cannondale.

For more information, visit fenixcommerce.com

Author: Akhilesh Srivastava

Founder and CEO of FenixCommerce